Shaft copying systems

Absolute positioning of the elevator car for travel heights of up to 392 m.

The non-contact absolute measuring system for shaft copying - also known as a shaft information or positioning system - is characterized by an extremely compact design and high robustness. In addition to the sensor, which detects the position of the elevator car 100% slip-free, it also includes the appropriate evaluation unit, a so-called Position Supervisor Unit (PSU). The safe system, consisting of a SIL3-certified sensor and matching evaluation unit. This enables elevator and safety functions to be implemented in accordance with EN 81-20/21/50.

Safe, precise, robust

- Delivery head up to 392 m

- Safety: SIL3 certified

- Dynamic: Travel speed up to 12 m/s

- Precise: Resolution up to 0.5 mm

- Direct: Absolute positioning.

Shaft copying systems

Absolute positioning of the elevator car for travel heights of up to 392 m.

The non-contact absolute measuring system for shaft copying - also known as a shaft information or positioning system - is characterized by an extremely compact design and high robustness. In addition to the sensor, which detects the position of the elevator car 100% slip-free, it also includes the appropriate evaluation unit, a so-called Position Supervisor Unit (PSU). The safe system, consisting of a SIL3-certified sensor and matching evaluation unit. This enables elevator and safety functions to be implemented in accordance with EN 81-20/21/50.

Sensors – reliable determination of position and speed values

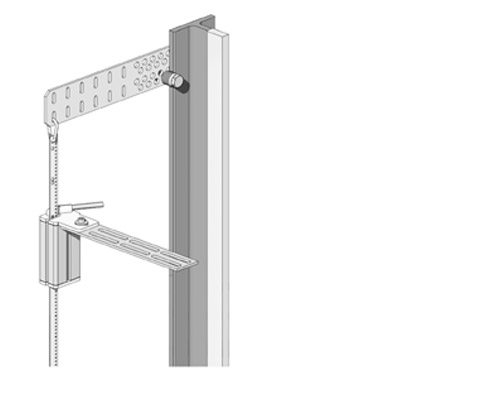

Mounting kit - simple and reliable mounting

Maximum system availability with maximum simplicity. Whether standard or backpack elevators, we have the right installation concept for our sensors for every application. Quick, easy and safe - Plug & Drive saves time and money.

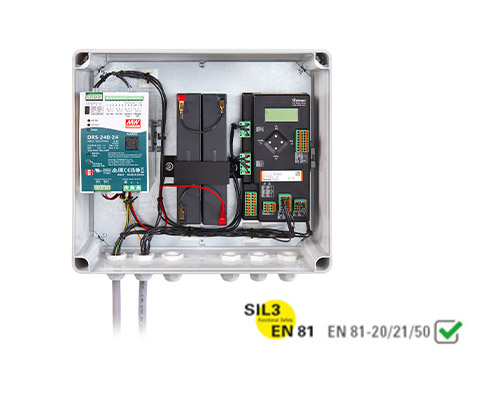

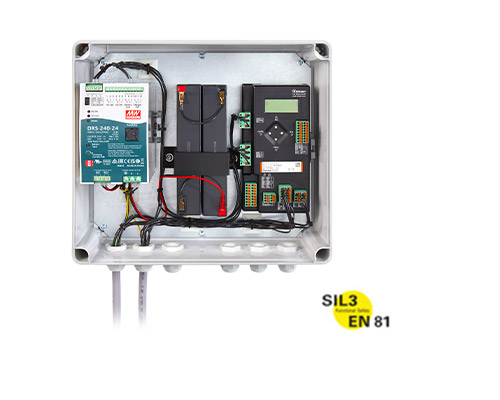

Evaluation units – Safe processing of position and speed data

MODBOX - system solution for modernization projects in elevator technology

The MODBOX is a control-independent solution for modernization projects in elevator technology. Housed in an IP66-rated plastic enclosure, it integrates the PSU03 or SGT03 evaluation unit, buffer batteries, and a power supply. The power supply is designed to match the power consumption of the installed safety gear. Thanks to the emergency power buffering, it is ensured that the safety gear can be released for emergency rescue even in the event of a blackout. All components inside the enclosure are pre-wired.

Safe systems – implementation of safety functions

Videos

Portfolio Ants shaft copying systems - german

Absolute and safe positioning of the elevator car up to 392 m. We present you the benefits of the Ants shaft copying systems.We present you the advantages of the Ants shaft copying systems as well as when and where Base, Safe or Safe System variants are used

DOWNLOADS

05.11.2024

LES02D - Dual CAN

19.02.2026

∼ 2.872 MB

Safe shaft copying systems

06.03.2026

Encoders for elevator motors

20.05.2025

∼ 15.054 MB

Short form Catalog 2025/2026

27.02.2026

∼ 2.809 MB

Shaft copying systems - Sensors

Due to a technical problem, our website is only available to a limited extent. This also affects our download service area. We are already working on the solution and ask for your understanding.

Due to a technical problem, our website is only available to a limited extent. This also affects our download service area. We are already working on the solution and ask for your understanding.