Speed measuring of the rotor and generator shaft

The optimal encoder for any wind speed with Kübler.

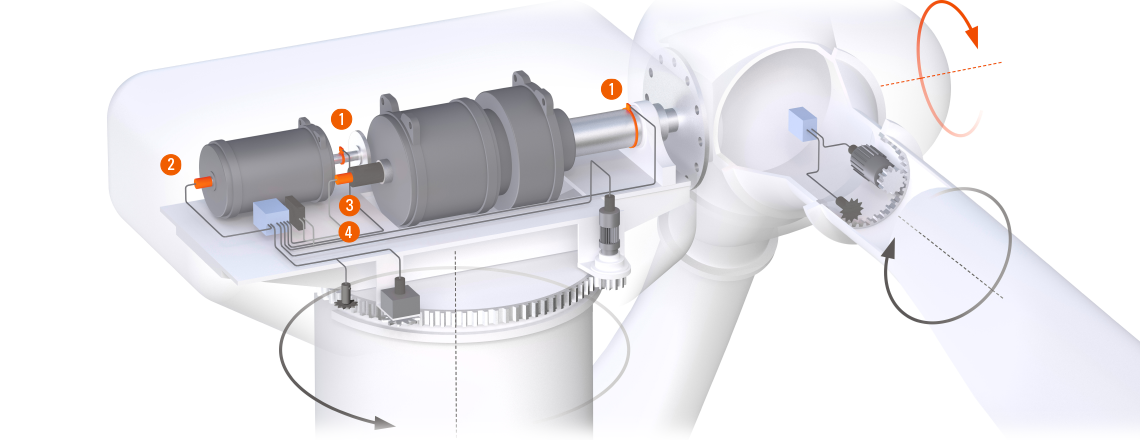

Accurate position and speed information are important measured variables for the control loop of a wind turbine. Kübler offers the right sensor solutions for this purpose: from extremely robust encoders for monitoring the generator speed at the shaft end, to compact encoders for integration in the slip ring, to bearingless encoders for direct speed detection at the rotor and generator shaft.

If necessary, smart bearingless encoders offer the highest resolutions and allow for a high control quality through digital signal processing with active correction of signal errors. The flexible encoder systems are true all-rounders. They provide information about the position, speed and acceleration and can be directly integrated into the condition monitoring system or into the system’s safety monitoring through additional outputs.

Precise and reliable

- Sturdy encoders – particularly resilient

- Bearingless encoders for large shaft diameters

- Optimal speed and position measuring

- Competent advice and high service quality

- Global presence – in over 50 countries

Speed measuring of the rotor and generator shaft

The optimal encoder for any wind speed with Kübler.

Accurate position and speed information are important measured variables for the control loop of a wind turbine. Kübler offers the right sensor solutions for this purpose: from extremely robust encoders for monitoring the generator speed at the shaft end, to compact encoders for integration in the slip ring, to bearingless encoders for direct speed detection at the rotor and generator shaft.

If necessary, smart bearingless encoders offer the highest resolutions and allow for a high control quality through digital signal processing with active correction of signal errors. The flexible encoder systems are true all-rounders. They provide information about the position, speed and acceleration and can be directly integrated into the condition monitoring system or into the system’s safety monitoring through additional outputs.

DOWNLOADS

11.08.2022

∼ 2.739 MB

Solutions for Wind Turbines

Due to a technical problem, our website is only available to a limited extent. This also affects our download service area. We are already working on the solution and ask for your understanding.

Due to a technical problem, our website is only available to a limited extent. This also affects our download service area. We are already working on the solution and ask for your understanding.