Solutions for the steel industry

High system availability: Speed measuring and positioning with Kübler sensors.

Sensors carry out important tasks in steel plants. Exposed to difficult environmental conditions, encoders must ensure a safe and interruption-free process. Reliability is the most important characteristic, especially in systems with very high operating costs. This is what the high level of sturdiness and premium quality of our products ensure. Kübler encoders have been providing reliable services in steel plants across the world for many years. You can trust our products too and find the right solution for your application.Robust and durable

- Incremental and absolute rotary encoders

- Fiber optic systems

- Functional safety

- Suitable for extreme applications

Solutions for the steel industry

High system availability: Speed measuring and positioning with Kübler sensors.

Sensors carry out important tasks in steel plants. Exposed to difficult environmental conditions, encoders must ensure a safe and interruption-free process. Reliability is the most important characteristic, especially in systems with very high operating costs. This is what the high level of sturdiness and premium quality of our products ensure. Kübler encoders have been providing reliable services in steel plants across the world for many years. You can trust our products too and find the right solution for your application.

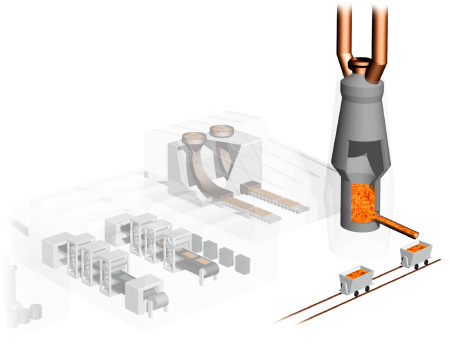

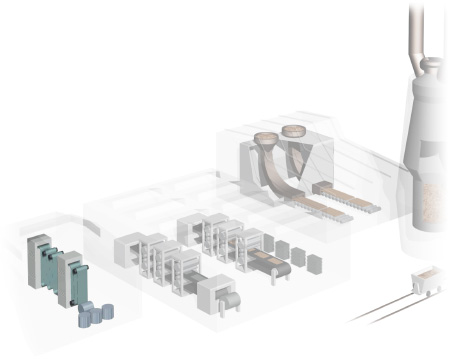

Steel formation

Positioning and speed regulation of crane systems and conveyor vehicles. Sturdy sensors in a very dusty environment with high mechanical requirements when it comes to shock and vibration resistance.

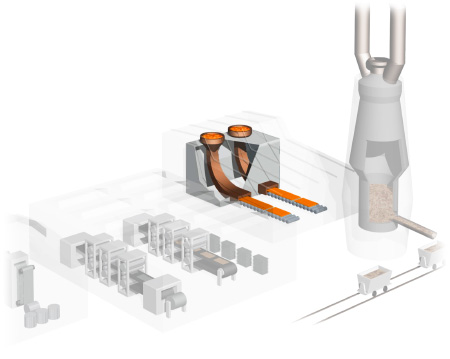

Cast steel

Rolling and cutting to length the continuous rod. Use of encoders in extreme temperatures.

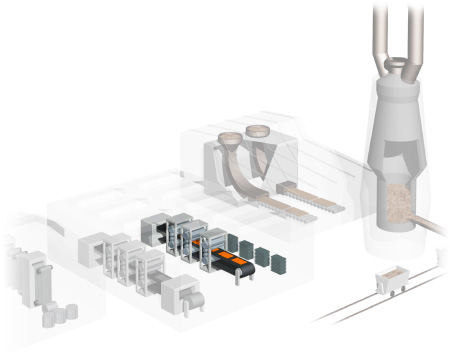

Hot rollers

Sturdy speed regulation and exact positioning of the rollers. Encoders in very hot and humid environments. Encoders suitable for rolling mills, shock-tested and with centrifugal force switches for protection against overspeed.

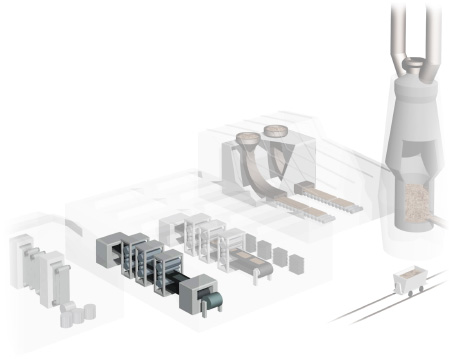

Cold rollers

Highly-dynamic speed regulation and exact positioning of the rollers. High speeds and strong vibration and shock loads. Positioning as well as speed and hoist control of crane systems.

Further processing

Highly-accurate speed regulation in electroplating plants. Encoders under the influence of humidity and many chemical substances. Positioning as well as speed and hoist control of crane systems.

DOWNLOADS

14.05.2024

∼ 6.932 MB

Solutions for Heavy Industry

Due to a technical problem, our website is only available to a limited extent. This also affects our download service area. We are already working on the solution and ask for your understanding.

Due to a technical problem, our website is only available to a limited extent. This also affects our download service area. We are already working on the solution and ask for your understanding.