Standard slip rings

Slip rings in a modular system: The optimal solution for every application.

Kübler slip rings stand for reliable transmission of electrical power, analog, or digital signals, as well as for transmission of field buses and Industrial Ethernet. Thanks to their modular design, the different contact technologies from contactless to contact systems, the possible combination with media lead-through for air and liquids, you have maximum flexibility in the configuration of your slip ring. We are also happy to meet individual requirements. We can handle modifications and special solutions for you quickly and without complications.

Transmission of power, signals, and data

- Maximum flexibility thanks to modular design

- Long service life – made in Germany

- Reliable contact systems

- Contactless signal transmission

Standard slip rings

Slip rings in a modular system: The optimal solution for every application.

Kübler slip rings stand for reliable transmission of electrical power, analog, or digital signals, as well as for transmission of field buses and Industrial Ethernet. Thanks to their modular design, the different contact technologies from contactless to contact systems, the possible combination with media lead-through for air and liquids, you have maximum flexibility in the configuration of your slip ring. We are also happy to meet individual requirements. We can handle modifications and special solutions for you quickly and without complications.

THE FLOW-PACK SPECIALIST

MODULAR CONSTRUCTION

Modular with Ethernet Datatransmission

The flow pack specialist

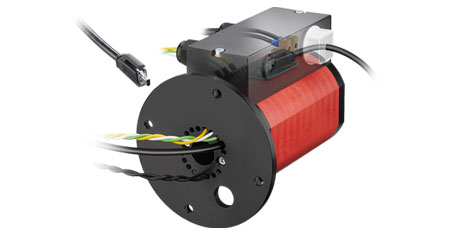

With a dimension of only 60 mm, the SR060 is a compact and economical slip ring for up to 3 load and 2 signal channels. It is used for heating and monitoring the sealing rollers of flow-pack machines. The food industry has particularly high requirements regarding cleanliness and hygiene. Open slip rings still frequently used here often lead to contamination by carbon abrasion of the slip ring brushes and are difficult to clean. The SR060E offers the ideal contamination-free solution with its fully encapsulated plastic housing and IP64 protection. The lifespan of 500 million revolutions sets standards. Long maintenance cycles of 100 million revolutions round out its strengths and make it the specialist for tubular bag machines.

To the SR060E slip ring

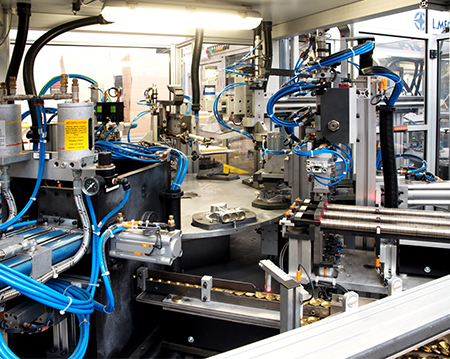

Maximum customization thanks to modular design

Thanks to its modular design, the SR085 slip ring adapts ideally to the carousel size of any textile machine. The reliable contact technology also enables the transfer of field bus data via the slip ring. High vibration resistance, long service life, and long maintenance cycles reduce machine downtime. The compact housing and easily accessible connections allow quick and easy installation.

To the SR085 slip ring

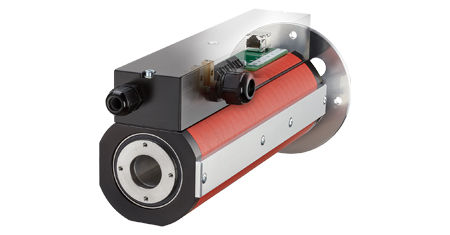

Integrated media lead-through and reliable transfer

No matter what is installed on the rotary indexing table – the SR085 with integrated media lead-through transmits loads and signals as well as pneumatics and hydraulics. The modular design with up to 21 channels offers maximum flexibility. The reliable contact technology also permits the reliable transfer of field bus data via the slip ring. High vibration resistance, long service life, and long maintenance cycles reduce machine downtime. The compact housing and easily accessible connections ensure quick and easy installation.

To the SR085 slip ring with media lead-through

DOWNLOADS

08.07.2024

∼ 2.482 MB

Slip Rings - Base-Line

29.03.2023

∼ 2.183 MB

Industrie 4.0 / IIoT ready

Due to a technical problem, our website is only available to a limited extent. This also affects our download service area. We are already working on the solution and ask for your understanding.

Due to a technical problem, our website is only available to a limited extent. This also affects our download service area. We are already working on the solution and ask for your understanding.