Rethinking elevator and safety functions - with intelligent safety gear management

When safety is re-evaluated - new answers are needed without mechanical components.

Mechanical systems have long been considered the standard in elevator technology. However, with stricter EU standards and increased requirements for tamper protection and reaction speed, they are increasingly reaching their limits. What used to be sufficient is now considered inadequate - and those who continue to rely on purely mechanical safety functions risk not only standstill, but also regulatory conflicts.

With components such as the PSU03 and SGT03, Kübler offers a digital safety architecture that integrates all relevant functions - including intelligent safety gear management. For projects that not only comply with standards, but are also future-proof.

- Intelligent safety gear management

- Elimination of mechanical components

- Plug & Drive

- Self-sufficient system

- MODBOX - with emergency power supply

Rethinking elevator and safety functions - with intelligent safety gear management

When safety is re-evaluated - new answers are needed without mechanical components.

Mechanical systems have long been considered the standard in elevator technology. However, with stricter EU standards and increased requirements for tamper protection and reaction speed, they are increasingly reaching their limits. What used to be sufficient is now considered inadequate - and those who continue to rely on purely mechanical safety functions risk not only standstill, but also regulatory conflicts.

With components such as the PSU03 and SGT03, Kübler offers a digital safety architecture that integrates all relevant functions - including intelligent safety gear management. For projects that not only comply with standards, but are also future-proof.

Elevator and safety functions – reliably realized digitally

Our components are more than just individual parts - they form a digital security architecture that intelligently networks all relevant functions. From the sensor to the evaluation to the catch release, a system is created that not only complies with current standards, but also flexibly maps future requirements.

A

A

Self-sufficient system Control-independent

Self-sufficient system that can be used as a retrofit kit for modernizing old (and modern) control systems.

B

B

UCM

Unintentional car movement

If the cabin leaves a defined door zone in an uncontrolled manner with the doors open, the safety circuit is opened or the electromechanical safety gear is triggered.

C

C

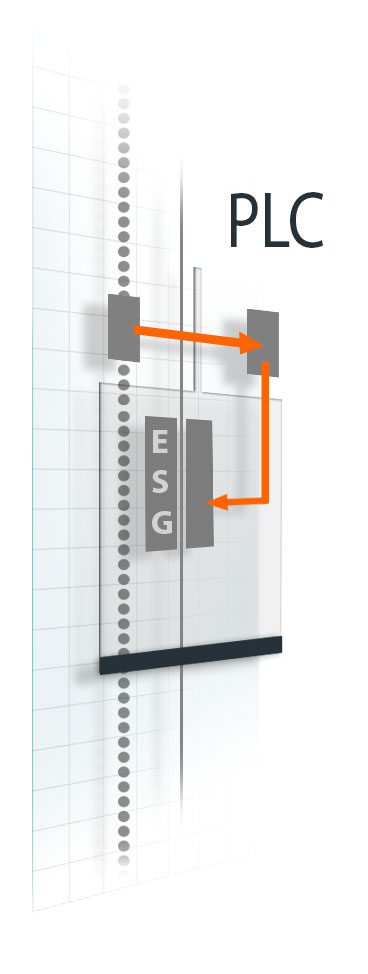

Overspeed triggering ESG

Elimination of the mechanical overspeed governor: In the event of overspeed, the safety circuit is opened or the electromechanical safety gear is triggered directly by the PSU03 / SGT03.

D

D

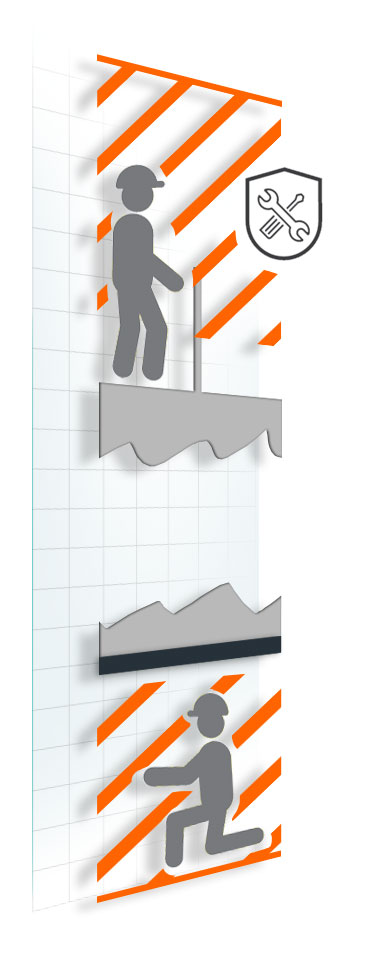

Shelter maintenance in shield mode

When entering the shaft with a reduced shaft head/pit in accordance with EN 81-21, the maintenance shield mode is activated via the door release. A protective space is created to allow maintenance personnel to work safely.

E

E

Shelters Mounting Shield Mode

Shield mode installation ensures a protected space for personnel even before the elevator is put into operation. During installation, such as rail fastening, a protective space is created sequentially according to the installation progress. Depending on the position, the cabin is secured with a tolerance of ± 5 cm.

F

F

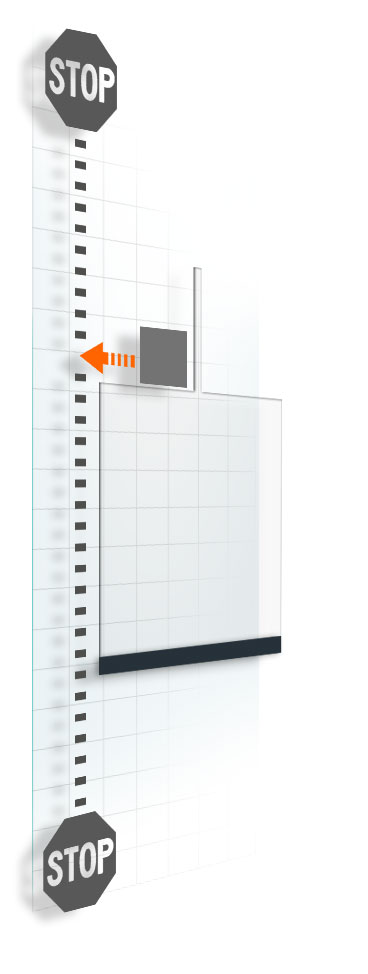

Absolute position feedback Emergency limit switch

The SIL3-certified measuring system consisting of Sensor Ants LES03 and Codeband determines both absolute position values and the speed of the car without slippage using a non-contact measuring principle. Many functions, such as emergency limit switches, can be implemented using this system.

When mechanics are no longer enough

New TÜV regulations and stricter safety standards present elevator operators with a clear decision: Continue with outdated technology - or take the step into the digital future with Kübler LES03 / PSU03.

| Function 1) | Standard notes | SIL | LES03 / PSU03 Safe positioning system with safety catch release |

LES03 / PSU03 Safe positioning system |

LES03 / SGT03 Safety catch release |

LES03 / SGT03 Safety catch release with limit switch and interlock control |

|

|---|---|---|---|---|---|---|---|

| A | Self-sufficient system (independent of the elevator control system) | No standard reference | - | ✔ | ✔ | ✔ | ✔ |

| B | UCM (Unintentional car movement) | EN 81-20: 5.6.7.7 | 2 | ✔ | ✔ | - | - |

| C | Release of safety catch at overspeed | EN 81-20: 5.6.2.2.1 a), 5.6.6.10 | 3 | ✔ | - | ✔ | ✔ |

| Monitoring status of safety gear | EN 81-20: 5.6.2.1.5 | 1 | ✔ | - | ✔ | ✔ | |

| Reset function of the electromechanical safety gear | No standard reference | 3 | ✔ | - | ✔ | ✔ | |

| Release of safety catch when car moves upwards | EN 81-20: 5.6.6.5 | 2 | ✔ | - | ✔ | ✔ | |

| Safety catch triggered by emergency brake switch | No standard reference | 3 | ✔ | - | ✔ | ✔ | |

| Safety catch switch that opens the safety circuit | EN 81-20: 5.6.2.1.5, 5.6.6.5 EN 81-21: 5.5.2.3.3 f), 5.7.2.3.3 f) |

1 2 |

✔ | - | ✔ | ✔ | |

| Monitoring of the electrical reset device | EN 81-21: 5.5.3.2, 5.5.3.3 c), 5.7.3.2, 5.7.3.3 c) | 2 | ✔ | - | ✔ | ✔ | |

| Shield mode: Safety release with reduced shaft head/pit to create a personal protection space | EN 81-21: 5.5.2.3.1, 5.7.2.3.1 | 2 | ✔ | - | ✔ | ✔ | |

| D | Shield mode: Creation of protective space during scaffold-free assembly | No standard reference | 3 | ✔ | - | ✔ | ✔ |

| E | Absolute position feedback | No standard reference | 1 | ✔ | ✔ | ✔ | ✔ |

| F | Emergency limit switch | EN 81-20: 5.12.2.3.1 b) | 1 | ✔ | ✔ | - | ✔ |

| Inspection limit switch with reduced shaft head/pit | EN 81-21: 5.5.3.4, 5.7.3.4 | 2 | ✔ | - | ✔ | ✔ | |

| Functional safety right from wiring (without presetting) | No standard reference | 3 | ✔ | - | ✔ | ✔ | |

| Delay control (with shortened buffer stroke) | EN 81-20: 5.12.1.3 | 3 | ✔ | ✔ | - | ✔ | |

| Pre-tripping overspeed 115 % (pretripping) | EN 81-20: 5.6.2.2.1.6 a) | 2 | ✔ | ✔ | ✔ | ✔ | |

| Monitoring the speed in inspection mode (0.63 m/s) | EN 81-20: 5.12.1.5.1 e) | - | ✔ | ✔ | ✔ | ✔ | |

| Secure configuration management for accelerated approvals | No standard reference | - | ✔ | ✔ | ✔ | ✔ | |

| Monitoring access to the car roof or shaft pit | EN 81-21: 5.5.3.1, 5.7.3.1 | 3 | ✔ | ✔ | ✔ | ✔ | |

| Door bridging | EN 81-20: 5.12.1.4 a), b), c), 2), d) | 2 | ✔ | ✔ | - | - | |

| Door zone signaling for emergency release in 12 V emergency power mode | No standard reference | - | ✔ | ✔ | - | - | |

| Buffer batteries for emergency release with power supply unit for ESG | no standard reference | ✔ | - | ✔ | - |

Mechanics are a thing of the past - discover the digital solution

The following components form the heart of our solution: they replace all outdated mechanical components with intelligent, standard-compliant modules. Whether for new projects or comprehensive modernizations - each unit is designed to maximize reliability and installation comfort.

Compatible with all electromechanical safety gears from Cobianchi, Dynatech and Wittur.

Preconfigured. Pre-wired. Thought ahead.

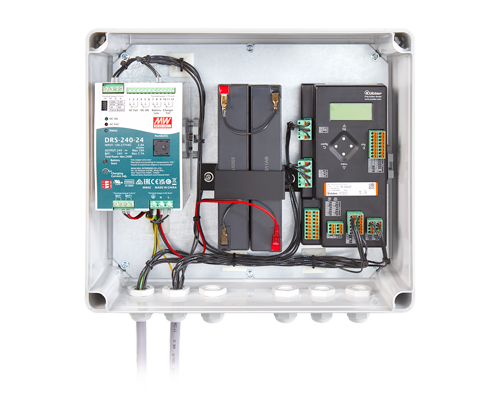

PSU03 including backup batteries and power supply unit

When it comes to safety-critical systems, it is not only the quality of the components that counts - but also how efficiently they can be integrated into existing systems. This is exactly where our MODBOX comes in: As a pre-assembled unit with pre-installed and pre-wired solutions, it reduces installation times, avoids interface errors and creates clarity in the project process.

Further concepts for our elevator solutions

Electronic speed limiter with intelligent safety gear management

Elevator and safety functions without intelligent safety gear management

19.02.2026

∼ 2.872 MB

Safe shaft copying systems

27.02.2026

∼ 2.809 MB

Shaft copying systems - Sensors

Due to a technical problem, our website is only available to a limited extent. This also affects our download service area. We are already working on the solution and ask for your understanding.

Due to a technical problem, our website is only available to a limited extent. This also affects our download service area. We are already working on the solution and ask for your understanding.