Intelligent fieldbus-independent communication

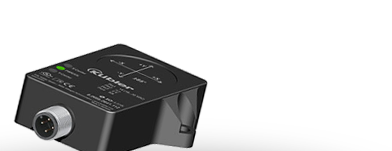

IO-Link master module. The central role in an IO-Link system.

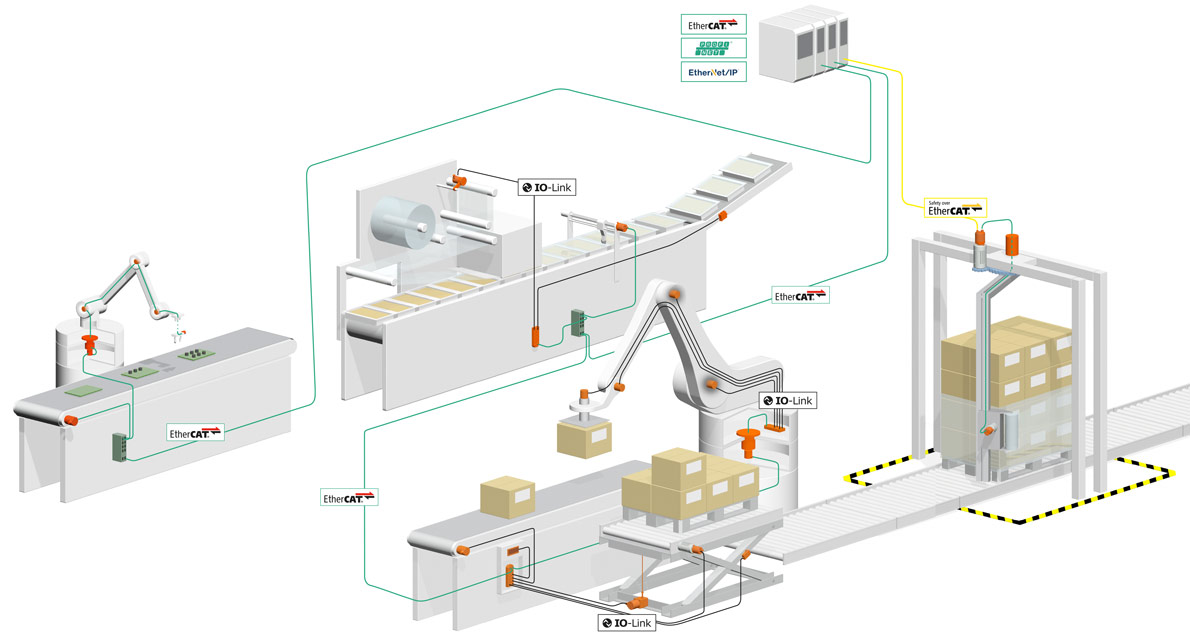

Discover the IO-Link master modules from Kübler and optimize your automation with state-of-the-art technology. The IO-Link master modules from Kübler reliably establish the connection between all IO-Link devices (sensors and actuators) and the higher-level controller (e.g. PLC). The bidirectional communication with the connected IO-Link devices enables parameters to be read and written. With reliable data transmission. In addition, the Kübler IO-Link Master Module collects diagnostic information from the devices and forwards it to the control system, which enables errors to be detected and rectified at an early stage. All in the spirit of condition monitoring and predictive maintenance.

Simple. Cost-efficient.

- Simple connection of all Kübler IO-Link products

- Bidirectional communication with any Ethernet protocol

- Reduced wiring effort - saves costs and time

- High system availability

Intelligent fieldbus-independent communication

IO-Link master module. The central role in an IO-Link system.

Discover the IO-Link master modules from Kübler and optimize your automation with state-of-the-art technology. The IO-Link master modules from Kübler reliably establish the connection between all IO-Link devices (sensors and actuators) and the higher-level controller (e.g. PLC). The bidirectional communication with the connected IO-Link devices enables parameters to be read and written. With reliable data transmission. In addition, the Kübler IO-Link Master Module collects diagnostic information from the devices and forwards it to the control system, which enables errors to be detected and rectified at an early stage. All in the spirit of condition monitoring and predictive maintenance.

Central parameterization and configuration: Increased efficiency through reduced maintenance effort.

The IO-Link Master provides central storage and automatic recovery of sensor settings, minimizing downtime and optimizing machine performance. When a sensor is replaced, the parameters are automatically transferred, significantly increasing efficiency and reducing maintenance. This centralized parameterization and configuration ensures smooth operations and higher productivity.

Increased system availability and operational reliability thanks to reduced maintenance.

In addition, the IO-Link master increases system availability and operational readiness by ensuring that machines remain operational for as long and as efficiently as possible. By continuously monitoring and providing diagnostic information, the IO-Link master enables faults to be detected at an early stage. This also improves operational reliability and noticeably reduces the time and effort required for troubleshooting and maintenance.

Greater flexibility and modularity reduce the need for customization.

IO-Link masters offer numerous ports for a variety of sensors and actuators, allowing machines to be designed modularly and flexibly. New components can be easily added or replaced without the need for extensive adjustments.

Efficiency and sustainability across the board

Minimized operational interruptions and optimized machine performance lead to smooth processes and higher productivity. Central parameterization, continuous monitoring and diagnostics enable early detection of faults. Sensors and actuators can be easily added or replaced. All this leads to significant cost savings and reduced maintenance, resulting in lower operating costs, improved efficiency and more sustainable, environmentally friendly operation of the entire system in the long term.

Product variety

Kübler offers you numerous suitable products for your IO-Link master system.

Due to a technical problem, our website is only available to a limited extent. This also affects our download service area. We are already working on the solution and ask for your understanding.

Due to a technical problem, our website is only available to a limited extent. This also affects our download service area. We are already working on the solution and ask for your understanding.