Encoders Absolute singleturn

Sendix F5858

|

|

For real-time communication: Industrial Ethernet encoders with EtherCAT interface and cyber security.

The new Sendix F58 EtherCAT optical absolute encoders set new standards in terms of performance and flexibility. With extremely short cycle times of up to 150 µs and a wide range of adjustable parameters, they are ideal for demanding real-time applications. Features such as distributed clocks, scalable resolutions, and comprehensive diagnostic options make the F58 the first choice for modern automation solutions. Thanks to firmware updates via the network, the system can be expanded at any time – ready for tomorrow‘s requirements.

Connectivity stands for the ability to communicate additional information and / or to be integrated in a network. This can take the form of additional interfaces such as OPC-UA (e.g. for additional edge communication) or Industrial Ethernet communication as well as a digital interface such as "BISS" or "SCS open link".

Identification is the ability to transmit technical information by means of an electronic data sheet / type plate. In addition, further information about the machine can be transmitted (e.g. information about the axis where the encoder is installed). Essentially, all the information required in the application for asset management is recorded here.

Diagnostics functions provide relevant information about the condition of the product (e.g. error messages) or indirect information about the application. For example, an integrated temperature sensor can indicate that the permissible working temperature range has been exceeded. Or integrated vibration sensors provide information on the condition of the power train bearings. Highly integrated bearingless systems in particular can provide reliable information here. Log and time stamp functions in Industrial Ethernet encoders make it possible to create lifetime histograms.

Adaptability refers to adaptability, which can take place on two levels:

- At the operational level, the parameters / settings of an encoder can be changed during operation, e.g. to optimize setup processes or to eliminate measurement errors with digital signal processing.

- Software updates can be carried out at system level at any time.

The range of functions for the implementation of Industry 4.0 / IIoT concepts can be subsequently extended in order to guarantee the future viability of the system. Therefore, all Kübler fieldbus and Industrial Ethernet encoders are available with a firmware update function as standard.

| Mechanical | |

|---|---|

| Dimension | Ø 58 mm |

| Shaft type |

6 mm shaft, with flat surface 10 mm shaft, with flat surface |

| Flange type |

Synchro flange / Servo flange Clamping flange Square flange Ø 58.00 mm ❏ 63,50 mm |

| Working temperature | -40 °C ... +80 °C |

| Protection level |

IP65 IP67 |

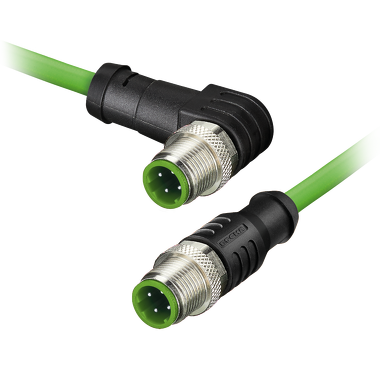

| Connection types |

M12 connector axial |

| Max. rotational speed |

9.000 min-1 |

| Weight | 310 g |

| Electrical | |

|---|---|

| Scanning | optical |

| Resolution max. |

19 bits singleturn |

| Power supply |

10...30 V DC |

| Interfaces |

EtherCAT |

| Options | |

|---|---|

| on request |

|

- Filter and variable integration time for different speed ranges.

- Support for cycle times up to 150 µs.

- Firmware update via EtherCAT FoE possible.

- Scaling of total resolution possible.

- Supports EtherCAT functions such as Distributed Clocks and Hot Connect.

- High position resolution up to 19 bits.

Benefits

- Suitable for time-critical applications with high update frequencies.

- Easy maintenance and updating in the field.

- For precise position and speed detection.

- Suitable for dynamic and high-precision applications and torque control.

- Suitable for use in maritime or industrial environments.

Warning: count(): Parameter must be an array or an object that implements Countable in /var/www/vhosts/kuebler.com/KDE_DEVELOPMENT/components/com_prod_drehgeber/views/drehgeber_edit/tmpl/default.php on line 405

| Software | ||

|---|---|---|

|

TwinCAT 3 Engineering |

Website |

Due to a technical problem, our website is only available to a limited extent. This also affects our download service area. We are already working on the solution and ask for your understanding.

Due to a technical problem, our website is only available to a limited extent. This also affects our download service area. We are already working on the solution and ask for your understanding.