Encoders Incremental

Sendix H120

|

|

For heavy duty applications – extremely robust hollow shaft encoders.

The incremental encoder Sendix H120 is ideal for large motors and generators. It is highly accurate and extremely robust thanks to HD-Safety-Lock™ - the Heavy Duty hollow shaft design of the latest generation with strong bearing construction and integrated bearing insulation. The double-protected shaft, the wide temperature range and the high protection enable use even under the most adverse conditions. The particularly large hollow shaft up to 28 mm, the variety of mounting solutions and connection variants offer maximum flexibility during installation.

| Mechanical | |

|---|---|

| Dimension | Ø 100 mm |

| Shaft type |

12 mm hollow shaft, blind hole 16 mm hollow shaft, through 20 mm hollow shaft, through 25 mm hollow shaft, through 28 mm hollow shaft, through 1 " hollow shaft, through 16 mm insert shaft, cylindrical 17 mm insert shaft, tapered |

| Flange type |

Ø 100.00 mm |

| Working temperature | -40 °C ... +100 °C |

| Protection level |

IP67 |

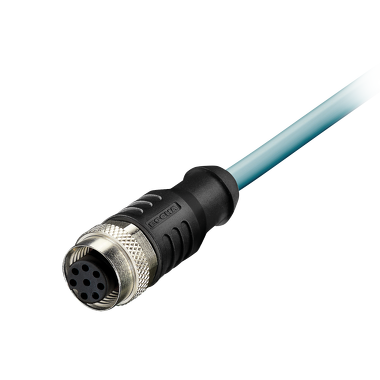

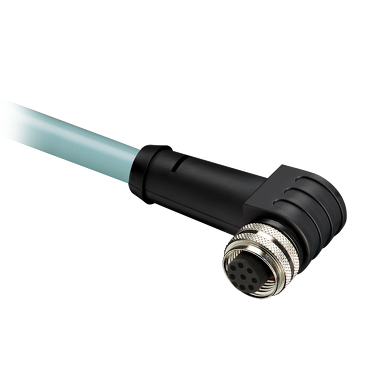

| Connection types |

Radial cable M23 connector radial M12 connector radial Terminal box |

| Max. rotational speed |

6.000 min-1 |

| Weight | 1800 g |

| Electrical | |

|---|---|

| Scanning | optical |

| Resolution max. |

5.000 ppr incremental |

| Power supply |

5 V DC 10...30 V DC |

| Interfaces |

Gegentakt TTL / RS422 |

| Options | |

|---|---|

| on request |

|

- Integrated bearing insulation of up to 2.5 kV for reliable shaft connection.

- Extremely high resistance due to double protection of the shaft (protective cover disc and radial shaft seal), IP67 protection as well as seawater resistant housing.

- High resistance to shock (200 g) and vibration (15 g).

- 3 mounting solutions: conical central mounting, cylindrical central mounting or through hollow shaft.

- Connection via cable, M12 or M23 plug or terminal box.

- Mounting arm on flange or cover. This means that the device can be rotated flexibly during mounting.

- Continuous hollow shaft up to 28 mm

Warning: count(): Parameter must be an array or an object that implements Countable in /var/www/vhosts/kuebler.com/KDE_DEVELOPMENT/components/com_prod_drehgeber/views/drehgeber_edit/tmpl/default.php on line 405

Accessories

Tether arm, 70 mm

For encoders A020, A02H, H120Mounting radius max. 135 mm

For applications with low axial and radial play, flexibly adjustable.

Scope of delivery

- Mounting arm

- 2 Allen screws M2.5 x 6

- 2 toothed lock washers

Connection to the application (not included in delivery)

- 1 screw

| 8.0010.40S0.0000 |

Tether arm, long

For encoder H120Mounting radius max. 136 mm

For applications with low axial and radial play, flexibly adjustable.

Scope of delivery

- Mounting arm

- 2 Allen screws M2.5 x 12

- 2 toothed lock washers

Connection to the application (not included in delivery)

- 1 screw

| 8.0010.40S1.0000 |

Tether arm, long

For encoders A020, A02H, H120Mounting radius max. 165 mm

For applications with low axial and radial play, flexibly adjustable.

Scope of delivery

- Mounting arm

- 2 Allen screws M2.5 x 6

- 2 toothed lock washers

Connection to the application (not included in delivery)

- 1 screw

| 8.0010.40T0.0000 |

Tether arm, long

For encoder H120Mounting radius max. 166 mm

For applications with low axial and radial play, flexibly adjustable.

Scope of delivery

- Mounting arm

- 2 Allen screws M2.5 x 12

- 2 toothed lock washers

Connection to the application (not included in delivery)

- 1 screw

| 8.0010.40T1.0000 |

Tether arm, 150 mm

For encoders A020, A02H, H120Mounting radius max. 215 mm

For applications with low axial and radial play, flexibly adjustable.

Scope of delivery

- Mounting arm

- 2 Allen screws M2.5 x 6

- 2 toothed lock washers

Connection to the application (not included in delivery)

- 1 screw

| 8.0010.40U0.0000 |

Tether arm, long

For encoder H120Mounting radius max. 216 mm

For applications with low axial and radial play, flexibly adjustable.

Scope of delivery

- Mounting arm

- 2 Allen screws M2.5 x 12

- 2 toothed lock washers

Connection to the application (not included in delivery)

- 1 screw

| 8.0010.40U1.0000 |

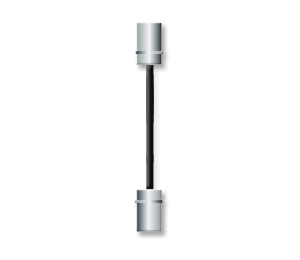

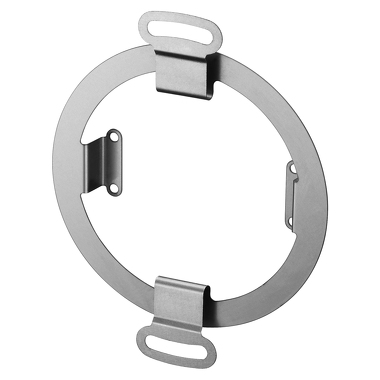

Stator coupling

For encoders A020, A02H, H120

Pitch circle diameter 59.5 mm

For applications with axial and radial play at high dynamics.

Scope of delivery

- Stator coupling (stainless steel)

- 4 screws for mounting on the encoder

Connection to the application (not included in delivery)

- 2 screws

| 8.0010.40V0.0000 |

Cables and connectors

„Do you have technical questions about Kübler encoders or are you looking for individual solutions? We at Application Support are here for you.“

Markus Zimmermann

Application Engineer„We will be pleased to give you information about prices and delivery times. We are looking forward to your inquiry.“

Due to a technical problem, our website is only available to a limited extent. This also affects our download service area. We are already working on the solution and ask for your understanding.

Due to a technical problem, our website is only available to a limited extent. This also affects our download service area. We are already working on the solution and ask for your understanding.