Encoders Absolute multiturn

Sendix F5883

|

|

Intelligent Scan Technology™ – powerful and economical at the same time.

The Sendix F58 Multiturn with patented Intelligent Scan Technology™ is a particularly high-resolution optical multiturn encoder without gears and with magnetically insensitive sensor technology. 41 bits total resolution, through hollow shaft up to 15 mm and versions with additional SinCos or RS422 incremental track.

| Mechanical | |

|---|---|

| Dimension | Ø 58 mm |

| Shaft type |

10 mm hollow shaft, through 12 mm hollow shaft, through 14 mm hollow shaft, through 15 mm hollow shaft, through 3/8 " hollow shaft, through 1/2 " hollow shaft, through |

| Flange type |

Ø 46.00 mm Ø 58.00 mm Ø 63.00 mm Ø 65.00 mm |

| Working temperature | -40 °C ... +85 °C |

| Protection level |

IP65 IP67 |

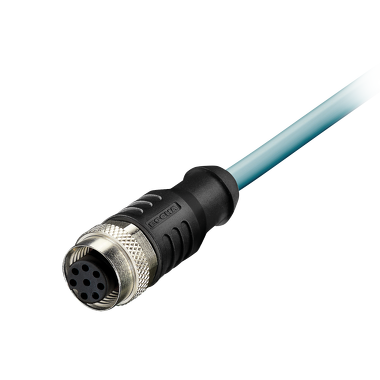

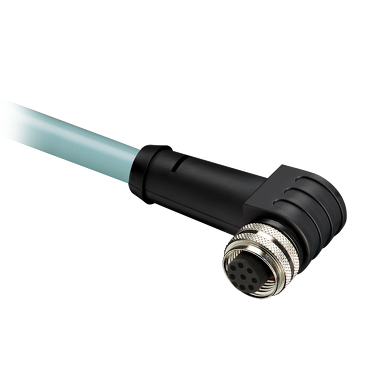

| Connection types |

Radial cable Tangential cable M23 connector radial M12 connector radial |

| Max. rotational speed |

9.000 min-1 |

| Weight | 450 g |

| Electrical | |

|---|---|

| Scanning | optical |

| Resolution max. |

2.048 ppr incremental 17 bits singleturn 24 bits multiturn |

| Power supply |

5 V DC 10...30 V DC |

| Interfaces |

SSI, binär SSI, gray SSI + 2048 ppr SinCos SSI + 2048 ppr RS422 BiSS |

- Robust bearing construction in Safety-Lock™ design for resistance to vibration and installation errors.

- Due to IP67 protection and wide temperature range from -40°C to +85°C also suitable for outdoor use.

- Patented Intelligent Scan Technology™ with all single and multiturn functions on one OptoASIC - thus highest reliability, a high resolution of up to 41 bit and with magnetically insensitive sensor technology.

- Available with SSI or BiSS interface and combined with SinCos incremental signals.

- The right fastening solution or type of connection is available for every application.

- Set button and LED for easy commissioning.

- High-resolution feedback in real time via SinCos and RS422 incremental outputs.

- Short control cycles, clock frequency SSI up to 2 MHz / BiSS up to 10 MHz.

Warning: count(): Parameter must be an array or an object that implements Countable in /var/www/vhosts/kuebler.com/KDE_DEVELOPMENT/components/com_prod_drehgeber/views/drehgeber_edit/tmpl/default.php on line 405

Accessories

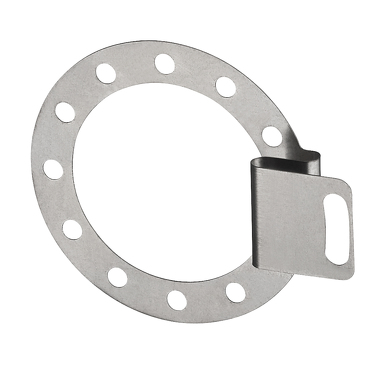

Stator coupling

For hollow shaft encoders

with flange ø 50 ... 58 mm

Mounting radius 32.5 mm

For lateral mounting on the encoder flange.

For applications with axial and radial play at high dynamics.

Scope of delivery

- Stator coupling (stainless steel)

- 4 screws for mounting on the encoder

Connection to the application (not included in delivery)

- 3 screws

| 8.0010.1602.0000 |

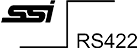

Torque stop, flexible

For hollow shaft encoders

with flange ø 58 mm

Mounting radius 39.5 ... 142.75 mm

Designed for functional safety technology.

For applications with axial and radial play at low dynamics.

Scope of delivery

- Torque support (stainless steel)

- 3 M3x6 screws for mounting on the encoder

Connection to the application (not included in delivery)

- 1 screw

| 8.0010.4047.00FS |

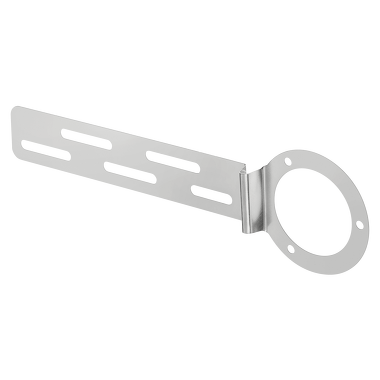

Fastening arm set, rigid

For hollow shaft encoderswith flange ø 58 mm

Mounting radius 32.5 ... 143.5 mm

Designed for functional safety technology.

For applications with very low axial and radial play at low dynamics.

Scope of delivery

- Torque support (stainless steel)

- 3 screws M3x6 for mounting to the encoder

Connection to the application (not included in delivery)

- 1 torque pin 8.0010.4049.0075

| 8.0010.4051.00FS |

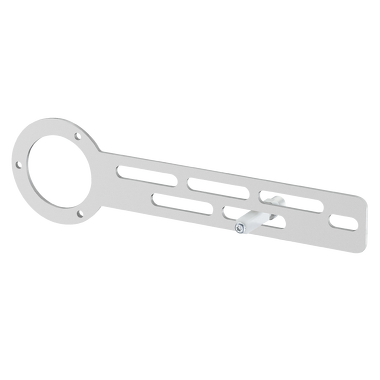

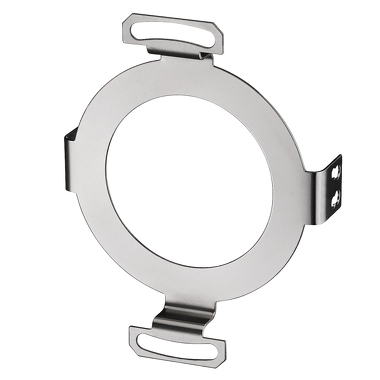

Stator coupling (FS)

For hollow shaft encoders

with flange ø 58 mm

Mounting radius 31.5 mm

Designed for functional safety technology by 4-screw principle.

Scope of delivery

- Stator coupling (stainless steel)

- 4 screws M3x6 for mounting to the encoder

Connection to application (not included in delivery)

- 4 screws

| 8.0010.40B2.00FS |

Fastening arm, medium (flexible)

For hollow shaft encoderswith flange ø 50 ... 58 mm

Mounting radius 32.5 ... 45.75 mm

For applications with axial and radial play with constant rotary movements.

Scope of delivery

- Torque support (stainless steel)

- 3 screws for mounting on the encoder

Connection to the application (not included in delivery)

- 1 screw

| 8.0010.40E0.0000 |

Stator coupling

For hollow shaft encoders

with flange ø 50 ... 58 mm

Mounting radius 32.5 mm

For lateral mounting on the encoder flange.

For applications with axial and radial play at high dynamics.

Scope of delivery

- Stator coupling (stainless steel)

- 4 screws for mounting on the encoder

Connection to the application (not included in delivery)

- 3 screws

| 8.0010.40L0.0000 |

Fastening arm, short (flexible)

For hollow shaft encoderswith flange ø 50 ... 58 mm

Mounting radius 32.25 mm

For applications with axial and radial play at low dynamics.

Scope of delivery

- Torque support (stainless steel)

- 3 screws for mounting on the encoder

Connection to the application (not included in delivery)

- 1 screw

| 8.0010.40M0.0000 |

Spring tether element

For hollow shaft encoderswith flange ø 50 ... 58 mm

For applications with low radial and axial play and low dynamics.

Scope of delivery

- Wire spring element

- 1 screw for mounting on the encoder.

Connection to the application (not included in delivery)

- 1 screw

| 8.0010.40W0.0000 |

Stator coupling, double-winged

For hollow shaft encoders

with flange ø 50 ... 58 mm

Mounting radius 31.5 mm

For lateral mounting on the encoder flange. For applications with high accuracy requirements.

Scope of delivery

- Stator coupling (stainless steel)

- 4 screws for mounting on the encoder

Connection to the application (not included in delivery)

- 2 screws

| 8.0010.4D00.0000 |

Spring element, short

For hollow shaft encoderswith flange ø 36 ... 58 mm

Mounting radius 16 ... 27 mm

For applications with limited axial play at low dynamics and limited installation space.

Scope of delivery

- Spring element (plastic)

- 1 screw for mounting on the encoder

Connection to the application (not included in delivery)

- Parallel pin 8.0010.4700.0000

| 8.0010.4H00.0000 |

Spring element, long

For hollow shaft encoderswith flange ø 36 ... 58 mm

Mounting radius 30.7 ... 36.7 mm

For applications with high axial play, at low dynamics.

Scope of delivery

- Spring element (plastic)

- 1 screw for mounting on the encoder

Connection to the application (not included in delivery)

- Parallel pin 8.0010.4700.0000

| 8.0010.4I00.0000 |

Fastening arm, long, (flexible)

For hollow shaft encoderswith flange ø 50 ... 58 mm

Mounting radius 36.5 ... 85 mm

For applications with axial and radial play at low dynamics.

Scope of delivery

- Torque support (stainless steel)

- 3 screws for mounting on the encoder

Connection to the application (not included in delivery)

- 1 screw

| 8.0010.4R00.0000 |

Due to a technical problem, our website is only available to a limited extent. This also affects our download service area. We are already working on the solution and ask for your understanding.

Due to a technical problem, our website is only available to a limited extent. This also affects our download service area. We are already working on the solution and ask for your understanding.